Analysis of recycling process of degradable film scrapsIssuing time:2021-02-19 09:40

The latest ban comes into effect in 2020

The implementation of the plastic ban is to promote the application of degradable packaging film (bag) in shopping malls, supermarkets, drugstores, bookstores and other places, fresh products degradable packaging film (bag). The bags made of plastic film are collectively referred to as plastic bags. The commonly used plastic bags are: convenience bags, supermarket bags, portable bags, flat pockets, plastic bags, horse traps and industrial bags.

What is a biodegradable plastic bag? It is made of non-toxic polyolefin resin, adding deoxidizer, starch, modified starch or other cellulose, photosensitizer, biological deoxidizer and other raw materials by film blowing process. Polylactic acid (PLA) is a biodegradable biologically based aliphatic polyester derived from renewable sources. PLA is the only transparent biodegradable material and has good gas resistance. Butyl phthalate (PKAT) can be blown and extruded for toughening modified polylactic acid. PLA/ PKAT biodegradable composite material expands the application of PLA in packaging industry. Blending PLA directly with PBAT can only improve toughness to a certain extent. The high price of the PLA also limits its promotion. Therefore, cornstarch can be used for filling.

Resources are limited and recycling is unlimited. The latest news in the plastic industry, recyclable plastic must be forced to add recycled materials for secondary production, supermarket shopping bag vest bag in the production process of waste B side material will produce 15-25%, plastic bag waste side material recycling is also imperative to the environment and resource regeneration.

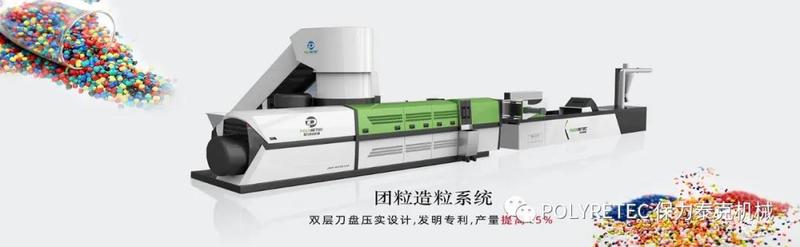

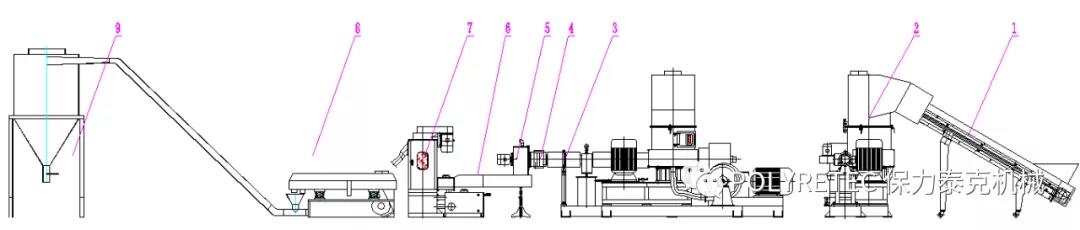

Degradable film scraps can be directly fed into the granulator Cut, break, shrink, agglomerate, extrude Process temperature: 120℃-140℃ Granulation method: water ring granulation Particle moisture content: ≤1% Particle appearance: round and full, no bubbles Color: white, off-white Production: 200-600 kg/h Regenerated particles can be directly added in the film blowing process |

Mobile site

Official WeChat